In the custom architectural millwork niche, the main thing to be considered is that of accuracy. Alongside the execution process, the characteristics of a design that are the most difficult properties to translate into wood are thus far when it is the implementation of the boldest and complex custom cabinetry, the finest finishing moldings, or the most appropriate furniture parts, and even after a couple of small changes to make it clear.

The millwork shop drawing package has to be the ultimate document for the job at hand, as it is the one that does the most to attract perfection in accuracy. And so, through this article, one can get a clear understanding of the topic of millwork shop drawings with which one will be directed right to the target.

Why Millwork Shop Drawings Are Simply Non-Negotiable

Millwork shop drawings are created by the contractor, subcontractor, vendor, manufacturer, or other entity that is responsible for the millwork construction. The “Means Illustrated Construction Dictionary Third Edition Unabridged” defines millwork as:

All the building products made of wood that are produced in a planing mill, such as moldings, door and window frames, doors, windows, blinds, and stairs. Millwork does not include flooring, ceilings, and siding.

Millwork shop drawings have become the most essential device of connection in the sphere where a slight deviation may cause a complete mess. Shop drawings are really indispensable as they are the document that:

- Nailing the Design: The draftsmen behind these drawings extract a very beautiful, yet rather raw, design concept to describe the specifications to their upper and under limits for the builder. By this way, the best cabinet or furniture in terms of surface and the client’s tastes, which is very satisfactory to both architects and clients alike, is gotten.

- Cutting Down on Costly Mistakes: Mistakes are an inevitable part of any field’s progress, although very costly. The drawings besides sidelining mistakes also act as the hindrance to the source of the expensive rework and the installation and making period that drag on for long.

- Making On-Site Coordination a Breeze: The shop drawings could be referred to as a simple language by which all teams are able to communicate. It is, therefore, the goal of the architects, together with the general contractors and the millworkers, always to be consistent in the course of their communication so that they can put each component with other components effectively at the site.

What Would Be in a Good Millwork Shop Drawing?

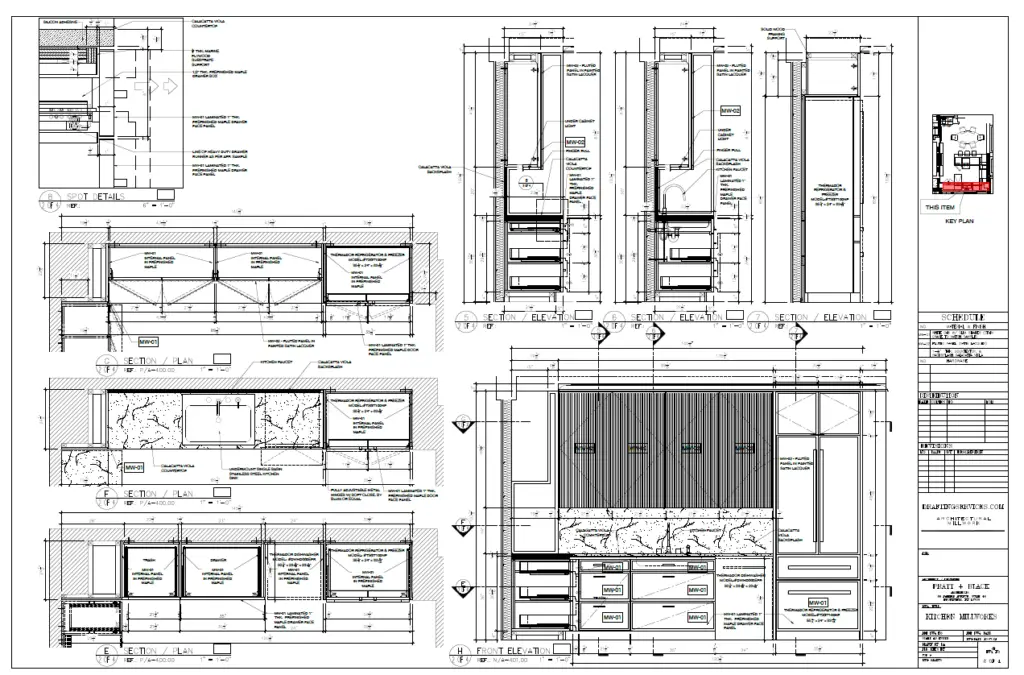

The complete package of millwork shop drawings is quite an extensive document. As a rule, you should expect to see there:

- Detailed Dimensions: The most thorough list can cover the size of everything from the biggest to the smallest part and also any necessary reveals and tolerances.

- Material Specifications: This would be the wood types and grades, veneers, laminates as well as all the finishes. Absolutely no guessing here!

- Construction & Joinery Methods: Clear diagrams of various connections, say, through dadoes, mortise and tenons, or a specific kind of fasteners.

- Hardware Schedules: This part should have all the details about the hardware, both functional and decorative, including their kinds, sizes, and points of their implementation.

- Blocking & Support Requirements: Notes are mentioning any kind of an internal or external overlay that is necessary for securing the installation.

- Interface Details: The detailed information is given on how the millwork is accommodated with the building and elements like walls, floors, or even where pipes or wires will go.

Afforded together, these aspects will furnish all the vital information on the custom woodworking projects.

How to Create Shop Drawings: A Step-by-Step Guide

Shop drawing generation in millwork is a well-thought, incremental activity, and the following describes the usual procedure of it:

- Collect Data: The first step should comprise gaining all relevant data, things like architectural drawings, specifications, schedules, and verified site dimensions. At this stage, a correct execution can’t be underestimated.

- Outline the Idea: Describe the initial design in a broader sense through creating initial layouts. This includes the drawing of plans, elevations, and sections primarily to know the rough shape and how it fits the space.

- Model in CAD Detailing: Now is the point of using software and file programs that are for your task. You will design very accurate and scalable drawings using the millwork software and CAD drafting programs (for instance, AutoCAD or Microvellum). And then you can include in this all the specifications and the assembly instructions.

- Incorporate All Necessary Information: In addition to shapes, include details of the manufacturing of the parts, specify the type of wood and finish, and prepare the final hardware list.

- Thorough Quality Check: Even after an in-house inspection, it is still necessary to do much work, however, you can kick off with line performance by putting your best into it. Always check before sending that nobody has made any errors, everything is uniform, and it synchronizes with the project requirements. This stage is really very significant, as no (potential) problems will escape without being discovered.

- Approval Process: The next task is to provide the whole set of plans to the architect, contractor, and customer and await feedback. Any project may be launched by the receipt of the latter’s approval only.

The Real Value of Professional Millwork Drafting

When the builders, contractors, and architects work together with an efficient millwork drafting team, their true blueprint has almost started to be visible. This is what gives you confidence of correct implementation of challenging custom woodworking projects from the word go. The approach takes the possibilities of errors to a minimum, simplifies the business of finance, and leads to highly-efficient, top-of-the-line millwork that is completely compatible with and indicative of the success of the respective sector of construction or interior design. Simply put, such projects are not possible without the issues of broken walls, incorrect layout, or measuring.

Contact

For professional assistance in developing precise millwork shop drawings, consider partnering with us at DraftingServices.com. Our expertise can help streamline the process and ensure that your project meets all specifications and standards.